Cement is one of the strongest adhesives in the world in the construction industry and is considered one of the main raw materials in most constructions.

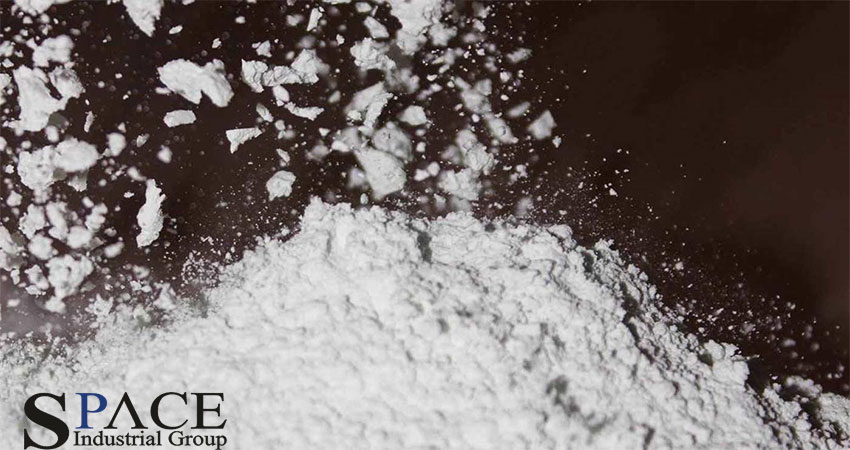

This substance is in a powder state and after mixing with water, it becomes a paste. In this article we intend to discuss issues such as the components of cement, its different types and the differences between different types of cement and also the application of each of them.

The ingredients of cement

Cement consists of various materials such as clay, silica, iron oxide, sodium oxide, magnesium oxide, potassium oxide and aluminum oxide, but its main ingredient is limestone. To produce cement, these materials are combined with each other, and the final product is obtained after a long process that includes mixing the materials together, baking them in the furnace, and grinding the materials that come out of the furnace.Different types of cement are produced according to the difference in preparation stages and changes in the percentage of materials mixed with each other, and different names are applied to each of them. But in a general classification, cement can be divided into white cement and gray cement.

Gray cement and its ingredients

When the main ingredients of cement, i.e. limestone and clay, are combined together, it becomes a bright color but the addition of inorganic oxides such as sodium and iron oxides darkens the color of cement and thus gray cement is produced. In addition, during the production stages of cement, the produced fumes are placed on the materials and this causes the darkness of the gray cement.

White cement and its ingredients

As mentioned in the previous section, the presence of compounds such as iron oxide in the composition of white cement causes its color to change and become darker. During the production of white cement, these materials that make the cement darker reach zero.

To produce this type of cement, a combination of limestone and white kaolin soil is used. During the production of gray cement, the baking temperature is lowered by using materials such as iron oxide or magnesium, but by removing them in the process of white cement production, the baking temperature is brought down using other elements such as gypsum, aluminum oxide, feldspar, etc. Also, although there are similarities in the production process of white cement and gray cement, the production of white cement is more complicated.

In the production of white cement, more precision is used than gray cement, and for the production of this material, advanced laboratories are continuously used to obtain the final product.

The difference between white and gray cement

As mentioned before, one of the reasons for the darkening of gray cement is the settling of soot resulting from the fuel of the furnace being fired on the material. During the production of white cement, manufacturers use soot-free fuels to prevent the white cement from darkening, and the price of these fuels is higher than the soot-containing fuels.

The production of white cement using fuels with a higher price, the complex process of white cement production and the high price of white cement composite materials cause the price of white cement to be higher than that of gray cement.

Use cases of white cement

White cement is mostly used in the stages of beautifying the building .It is beautiful and has high resistance. This type of cement is used for whitewashing the exterior of buildings. Since this type of cement is highly resistant to moisture and temperature changes. Its use in construction gives a special beauty to various buildings.

Among other applications of this type of cement, we can point out laying ceramic tiles or exterior stones.

Of course, it should be noted that there are different types of white cement, but in general, white cements are produced from lime. Due to the many advantages of this type of cement, its use is highly popular among the general public, and its use in building facades is one of its main uses, and as a result,this type of cement has become one of the most important and efficient materials in the construction industry.

Why white cement is better?

One of the main ingredients of white cement is calcium silicate, and this cement stands for white Portland cement. In the process of producing this cement, you

will be allowed to add 5% of limestone from the cement weight. The process of making white cement is much better than gray cement and it is mainly used for decorative purposes.

In addition to building materials, white cement is also used in decoration materials stores to make decorative items.Moreover, the applications of this type of cement in various types of architectural decoration materials, paintings, sculptures, common floors and terraces are important. White cement can also be used to produce white and colored concrete.

Gray cement is also known as natural cement because the price of this type of cement is lower than white cement, and it is widely used in construction materials. But when preparing the cement you need, you should pay attention to the fact that the production process of white cement is much better and better materials are used for its production.

Conclusion

The role of cement in the construction industry is very important and because of its high adhesive strength, it is widely used all over the world. The combination of different materials and elements with limestone produces different types of cement, the two main types of which are white and gray cement.

The way cement is produced and its components have a significant effect on changing the function and structure of cement. White cement has a more complex and better production process, and the high strength and resistance of this type of cement has made its quality higher compared to gray cement.

I used your cement and it was cost-effective

thank you for your feedback! We’re glad to hear that you found our cement cost-effective and efficient

Interesting! Which one is better for exterior finishes in hot climates?

Great question! White cement is often preferred for exterior finishes in hot climates because it reflects more sunlight and stays cooler, helping maintain the appearance and durability of the surface.

That’s interesting.

Glad you think so! 😊

Thank you for your helpful comparison.

You’re very welcome — I’m glad you found it useful!

Great article! Thank you for sharing such valuable insights — it was truly informative and well-written.

Thank you so much for your kind words! I’m glad you found it useful — your feedback truly means a lot.